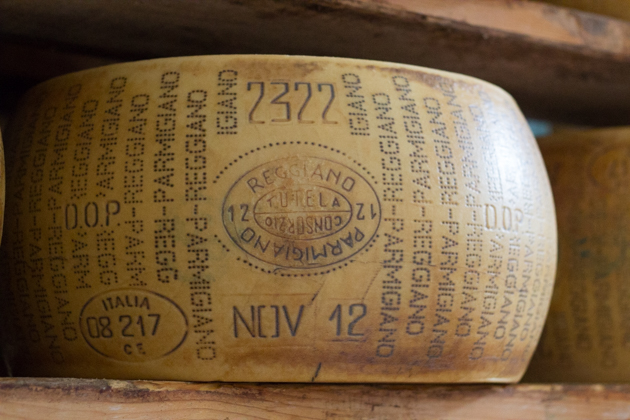

A wheel of Parmigiano-Reggiano cheese (the real Parmesan)

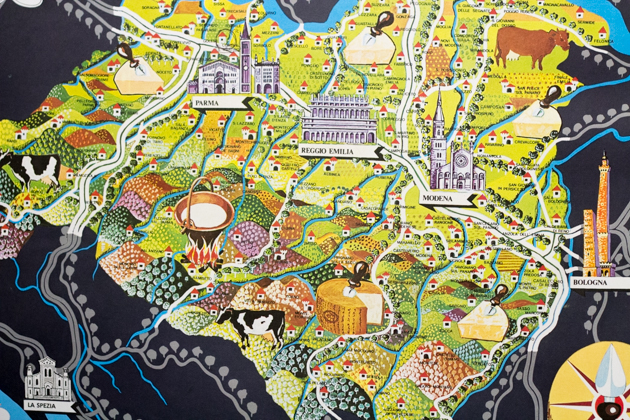

Parmesan is one of the most famous cheeses in the world and is an ubiquitous presence on the table of any Italian restaurant. What is less known is that anything labeled “Parmesan” is not in fact Parmesan. In fact the name “Parmesan” is no longer permitted to be used within the European Union. What was true Parmesan is now called Parmigiano-Reggiano and can only be made in the area spanning from Parma to Mantova under strict conditions regulated by the Parmigiano-Reggiano consortium. It is a product protected by the EU (PDO – Protected Designation of Origin).

Map of the production area for Parmgiano-Reggiano

Parmigiano-Reggiano cheese is rich in calcium (232 mg in 20 gms!), phosphorous and vitamins. It is also rich in protein (6.6 gms in 20 gms), low in cholesterol and is easily digestible. Doctors in Italy often recommend it for children, the elderly, athletes and new mothers. In Italy it is served on its own, drizzled with traditional balsamic vinegar, as an accompaniment to vegetables, nuts or fruit or is shaved onto pastas, soups (or just the rind added while cooking for an extra depth of flavour), salads or main dishes.

Parmigiano-Reggiano with balsamic vinegar and bresaola

Rows of cauldrons full of milk

Today there are about 200 producers of Parmigiano-Reggiano ranging in size from producing 4 cheeses a day to 100 wheels a day. They are limited by the number of cauldrons (each cauldron can produce 2 cheeses and they are only issued enough official stamps for the number of wheels they can produce in one day).

The tables the milk sits in during the night to separate the cream

The windows are opened to allow the milk to breathe

Morning milk is added to the evening milk and churned

The curd being collected in linen cloth

The bundles of curd are tied up

The curd being cut in half

Strong men lifting the 50 kilo bundles of curd

The curd is dipped in cold water to cool it

The curd is placed in a mould

The curd is weighed down to press out excess liquid

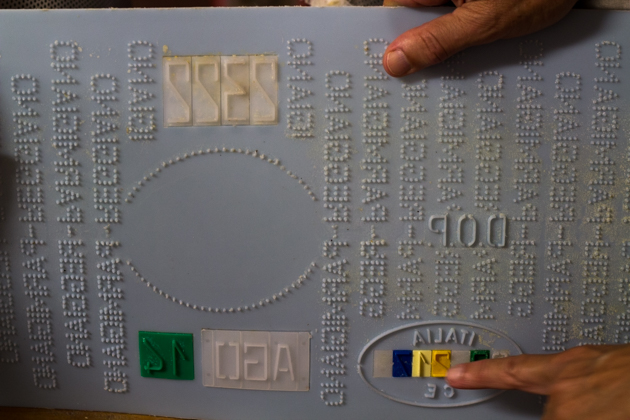

The EU issued markings pressed into the cheese indicating it is authentic Parmigiano-Reggiano

The press to imprint markings into the cheese

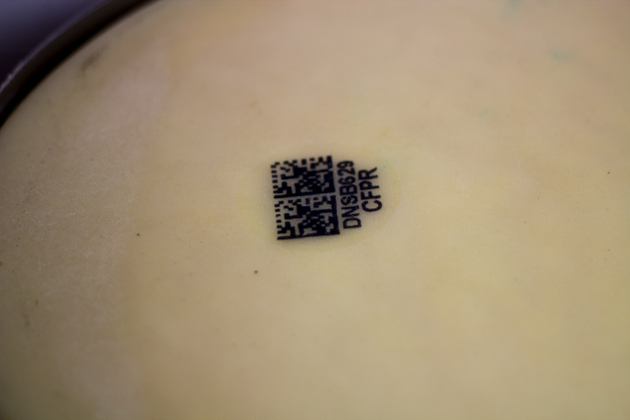

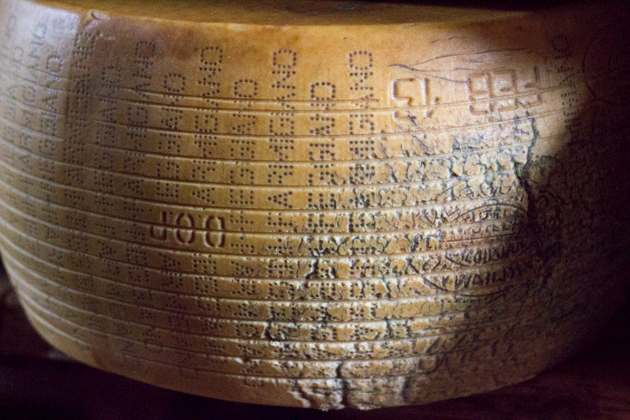

EU scannable coding to identify each wheel of cheese

Cheese being brined (note salt pile on right which gets absorbed if the salinity drops)

We entered a silent, dark room filled with long tubs. This is where the cheese is then soaked in a salt-water brine (using Mediterranean salt) for 20 days in order to salt the cheese to flavour and preserve it. The size of the wheels of cheese have increased over the past 100 years as with the larger size the cheese attains the correct texture and salinity. The salt sits in a perforated tub, the water adjusting the salinity itself to ensure equilibrium. The cheese is turned every day using a stick.

The wall of cheese

The robot that brushes the cheeses

Finally we walked into a huge warehouse which was filled with several solid walls 10 meters tall of cheese. This is where the cheese is matured for up to 24 months or more to develop texture and flavour. A robot was moving up and down the walls of cheese, removing a wheel, brushing it and placing it back. The cheese is continually brushed to keep it clean.

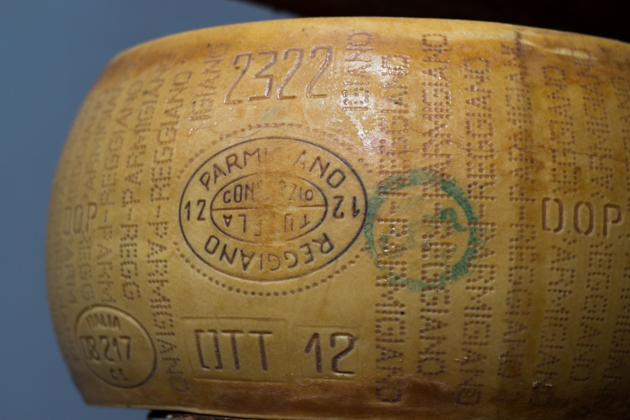

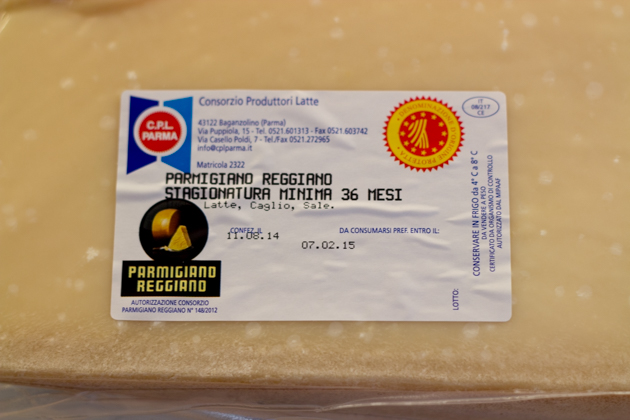

A wheel of Parmigiano-Reggiano cheese ready for the market with the green stamp and oval Parmigiano Reggiano Consorzio Tutela imprint

The stool they place the wheels of cheese to test them

After 12 months, an expert cheese tester arrives, places the cheese on a heavy stool and knocks on the cheese with a mallet, listening intently for the correct uniformity of sound. Only once he has approved the cheese with a green marking can it become “Parmigiano-Reggiano” and be branded with the oval mark reading, “Parmigiano Reggiano Consorzio Tutela” with the year of production.

Imperfect Parmigiano-Reggiano marked by grooves

The cheeses are categorised by their age with “Parmigiano Reggiano Mezzano” indicating the cheese is young, not much more than 12 months old indicated by grooves around the circumference of the wheel. Imperfect Parmigiano-Reggiano are also marked with grooves and sold before 18 months at a discount.

Wheels of Parmigiano-Reggiano

More mature “Parmigiano Reggiano” can be inspected again at 18 or 24 months or more. If they meet the higher standard, they can be stamped with “Export” or “Extra”. The most prized is between 24 to 30 months when it is soft yet has pockets of crystals.

Notable markings are the black “Parmigiano-Reggiano” stamp on the bottom left and the yellow and red “Denominazione d’Origine Protetta” in the upper right corner

this was very interesting but had nothing to do with your title. Why not buy Parmesan? and What to buy instead?

Hi Elaine, Thank you for posting. I should have made this more clear and will edit the post now. Parmesan was renamed Parmigiano-Reggiano because there were too many people copying it but not using the same process and maintaining the high standards of quality. Parmesan now means a cheese made somewhere outside Europe using any process with or without any standards of quality. Parmigiano-Reggiano is from the vicinity of Parma and is made using the process I describe and held to the quality standards I describe. So if you see a cheese labelled “Parmesan” in the store, it could be anything. You should look for the label to say “Parmigiano-Reggiano” and look for the markings I describe. Instead of buying Parmesan, buy Parmigiano-Reggiano instead. I hope that is clear.

Why is Tutela included in the stamp? That’s our last name and saw it recently on a trip to Florence. Just curious!

Thank you-

Dana

Hi Dana, “Tutela” means “protection” or “guardianship” so in this case, the origin and production of the Parmigiano-Reggiano is protected by the Parmigiano-Reggiano consortium (consorzio). The cheese only receives this marking once the consortium has inspected the cheese and approves it. Anyway it is a nice meaning for a family name. Hope this helps!

Yea yea yea, I know… the canned grated crap is still gonna be crap. That’s why I only get the GOOD grated cheese (the stuff in the plastic bags at the grocery store). Believe me, once you get THIS stuff, you’ll stick with it forever and will NEVER change!!

This might be too late for a reply, but I’d like to know what is in the marking inks used in production? Is it safe to eat the crusts with marking ink?

Hi Susan,

Thanks for the great question. It’s been a while now since I watched the production so I reached out to the Consortium for Parmigiano-Reggiano and there is no ink used at all. Here is their very detailed reply:

Surprisingly, there is no ink on the Parmigiano Reggiano rind!

The marks of origin are engraved during the first hours of life of the wheels using the stencilling band all around the cheese rind. The information provided is:

• dotted wording Parmigiano Reggiano

• PDO and Consortium inscriptions

• dairy identification number (in 3 different positions)

• month and year of production (in 3 different positions)

• identification mark (health requirement identifying the production plant)

The casein plate applied on one of the two flat surfaces of the wheel during its very first hours of life bears a unique and progressive alphanumeric traceability code which allows to trace the day when the wheel was born and in what dairy. This is made of casein, an edible protein.

The grade selection mark is engraved at the end of the 12 months of maturation, on those wheels that pass the quality inspection to which all the wheels produced are subject. The inspection is carried out by quality inspectors of the Consortium and following the certification issued by the PDO control body, the mark is hot-iron branded in an indelible way.

The rind is made of the same three ingredients of the cheese: milk, salt and rennet. There is no wax on it and therefore is absolutely edible!

Hope that gives you some comfort. I often put the rind in soups and broth so it makes me quite happy to know this. Thanks for asking.